Trimfix Supplies is proud to be Australia's official agent of

Wegener Plastic Extrusion Welders - high quality German made machines.

Exweld Mini FC Plastic Extrusion Welder

The Exweld Mini is the lightest and most compact wegener plastic extrusion welder.

Suitable for welding of 4 mm PE and PP

- Basic material pre-heating by special contact welding shoe

- Only 230 V electrical connection required (also for the option preheater)

- Gentle extrudate processing by continuous plasticizing process

- Electronic temperature control

- Outstanding manageability by low weight and small Dimensions

- Easy to exchange novel welding shoes, individual configuration available

- Scope of delivery includes a device support and a welding shoe of your choice

Mini FC Information Brochure .pdf

Download File

Specifications

Weight: 2.5-2.9kg

Welding Rod Profile: 4mm Round PE

Plastic Output per hour: 0.7kg PE

Sheet Welding Thickness: 3mm – 10mm

Nozzle Type: Locked Type

Material: PE

Exweld Aero Plastic Extrusion Welder

Professional High Work Load Swiss Made Plastic Welder

The Exweld Aero uses the heat from the heat gun to also heat the extrusion barrel.

This unique design reduces the overall weight of the tool by removing the need for separate heating elements inside the extrusion barrel. This gives users the benefit of the higher 2.6kg per hour output whilst also minimising the total size and weight of the tool.

Specifications:

Weight: 5-5.8kg

Welding Rod Profile: 3mm, 4mm Round (PP and PE)

Plastic Output per hour: 2.6kg PE – 2.2kg PP

Sheet Welding Thickness: 6mm – 20mm (approx)

Nozzle Type: Twisty

Material: PE

Sigma Plastic Extrusion Welder

The Sigma Plastic Extrusion Welder is a robust machine which provides precision temperature controls for both the preheater and the extrudate.

- Suitable for welding PE, PP, PVDF and other thermoplastic materials

- Streamline design with solid, durable construction

- Easy to operate, quick material changeover

- Lockable drive motor and multi-position handle

- Patented, trouble-free rod intake system

- Dual channel temperature controller for extrudate and preheat with cold start protection and monitoring of setpoint/actual temperatures

- Sophisticated extrusion screw and melting chamber with cartridge heating system allows for smooth and optimum processing of extrudate

- ‘Twisty’ rotatable welding head assembly standard

- EC model requires external air supply – see DT 10 blower (optional air flow meter available for use with shop air)

- Optional heavy-duty shipping/transport case with rollers

Specifications:

Weight: 5.4-5.6kg

Welding Rod Profile: 3mm, 4mm , 5mm Round PE – 3mm, 4mm PP

Plastic Output per hour: 1.9kg PE – 1.8kg PP

Sheet Welding Thickness: 5mm – 15mm (approx)

Nozzle Type: Twisted or Locked

Materials: PE, PP, PVDF and other weldable thermoplastic material

Specifications:

Weight: 6.4-7kg

Welding Rod Profile: 3mm, 4mm , 5mm Round PE – 3mm, 4mm, 5mm PP

Plastic Output per hour: 2.6kg PE – 2.2kg PP

Sheet Welding Thickness: 5mm – 25mm (approx)

Nozzle Type: Twisty or Locked

Materials: PE, PP, PVDF and other weldable thermoplastic material

Exweld Alpha 3 Plastic Extrusion Welder

The Exweld Alpha Plastic Extrusion Welder is a versatile machine suited to a wide range of plastic thicknesses.

- Suitable for welding PE, PP, PVDF and other thermoplastic materials

- Steamline design with solid, durable construction

- Easy to operate, quick material changeover

- Lockable drive motor and multi-position handle

- Sophisticated extrusion screw and melting chamber with cartridge/band heating system allows for smooth and optimum processing of extrudate

- Dual channel temperature controller for extrudate and preheat, cold start protection

- Unmatched relation between welding capacity, weight and price

- Electronically controlled drive motor with variable welding speed

- Patented, trouble-free rod intake system

- Adjustable preheat extension

- Solid, durable construction, easy operation

- Exchangeable PTFE welding shoes can be easily machined to determine weld size and configuration

- Optional heavy-duty shipping/transport case with rollers

- Special model with corrosion-resistant components for PVC/CPVC

- Multi-position handle

Exweld Beta Plastic Extrusion Welder

The Exweld Beta is a high output plastic extrusion welder.

- Suitable for welding PE, PP, PVDF and other thermoplastic materials. PVC optional

- Suitable for welding PE, PP, PVDF and other thermoplastic materials

- Streamline design with solid, durable construction

- Easy to operate, quick material changeover

- Lockable drive motor and multi-position handle

- Patented, trouble-free rod intake system

- Dual channel temperature controller for extrudate and preheat with cold start protection and monitoring of set-point/actual temperatures

- Exchangeable PTFE welding shoes are easily machinable to determine weld size and configuration

- Sophisticated extrusion screw and melting chamber with cartridge/band heating system allows for smooth and optimum processing of extrudate

- Self-contained air supply with brushless preheater

- Optional heavy-duty shipping case available

Specifications:

Weight: 10-10.7kg

Welding Rod Profile: 3mm, 4mm , 5mm Round PE – 3mm, 4mm, 5mm PP

Plastic Output per hour: 4.6kg PE – 4.3kg PP

Sheet Welding Thickness: 12mm – 40mm (approx)

Nozzle Type: Twisty or Locked

Materials: PE, PP, PVDF and other weldable thermoplastic material

Specifications:

Weight: 10.1kg

Welding Rod Profile: 3mm, 4mm , 5mm Round PE – 3mm, 4mm, 5mm PP

Plastic Output per hour: 6.2kg PE – 5.6kg PP

Sheet Welding Thickness: 12mm – 40mm (approx)

Nozzle Type: Locked

Materials: PE, PP, PVDF and other weldable thermoplastic material

Exweld Gamma 3 Plastic Extrusion Welder

The Exweld Gamma 3 is a robust high output plastic extrusion welder able to weld plastic sheet ranging from 20-50mm thickness at a rate of 6.2kg per hour.

- Suitable for welding PE, PP, PVDF and other thermoplastic materials

- Streamline design with solid, durable construction

- Easy to operate, quick material changeover

- Lockable drive motor and multi–position handle

- Patented, trouble-free rod intake system

- Dual channel temperature controller for extrudate and preheat with cold start protection and monitoring of set–point/actual temperatures

- Exchangeable PTFE welding shoes are easily machinable to determine weld size and configuration

- Sophisticated extrusion screw and melting chamber with cartridge/band heating system allows for smooth and optimum processing of extrudate

- Requires external air supply– see DT 10 blower (optional air flow meter available for use with shop air)

- Optional heavy–duty shipping case available

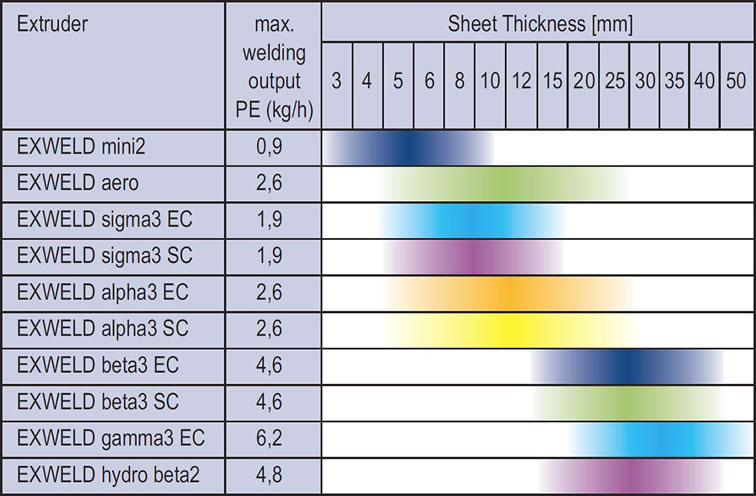

Wegener Plastic Extrusion Welder Selection Guide

Find out which model plastic extrusion welder will best suit your plastic welding requirements.